Welding work

Gas detectors for welding work in potentially explosive areas

Precise and safe gas detection effectively increases personal safety when welding in potentially explosive areas.

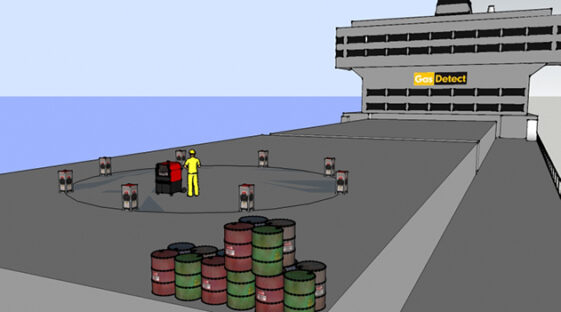

Gas detection is often a necessity or mandated due to the risk of explosion when welding, cutting and drilling in material or machinery located in potentially explosive areas. If the concentration of explosive gases is high, the welding work can quickly lead to an explosion with personnel and material damage as a result. It is therefore crucial that the concentration is closely monitored.

Hand-held gas detectors can be carried by the workers, just as mobile area detectors can be placed around the environment. The units give an alarm even at low concentrations, just as the power to the construction board or welding plant is interrupted in the event of a leak. Effective gas detection ensures that a potentially dangerous situation is prevented in time.

The gas detectors continuously monitor the concentration of explosive gases and give an alarm at known limit values. The monitoring system ensures automatic control of power supply, ventilation and alarm with flash and horn for quick evacuation. You comply with all safety requirements, effectively reduce the risk of explosion and increase workplace safety for you and your colleagues with gas detection equipment from GasDetect A/S.

Specialists in gas detection

GasDetect A/S are specialists in gas detection. With us you will find a large selection of gas detectors particularly suitable for explosive areas. You can see a selection of our popular products below.

We guarantee quality equipment with high durability and a long service life. That is why we carry only the best products from the world’s leading manufacturers. Increase personal safety at your workplace. Contact GasDetect A/S today.

Our experienced experts are of course ready to advise you on the solution that matches your specific case, needs and requirements.